powder coat reconditioning Process

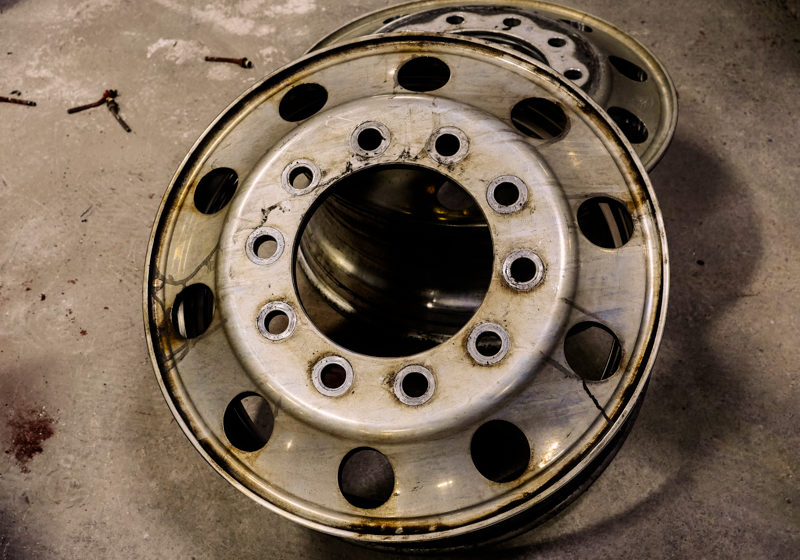

Thorough Inspection

Each incoming wheel is thoroughly inspected for cracks, rust-through, or other damage that may make the wheel unserviceable. Wheels found unfit for service are removed from the process.

Cleaning

Each wheel is thoroughly cleaned using our proprietary cleaning process, then re-inspected.

Zinc Coating

A zinc coating is applied to the entire surface area of the wheel. The zinc acts as a metal preservative which slows, or even stops, the rusting process.

Powder Coating

Each wheel is powder-coat painted by hand to ensure complete coverage.

Curing

Painted wheels undergo a curing process to harden the finish.

Final Inspection

Every finished wheel is subjected to a final inspection to guarantee a like-new appearance.

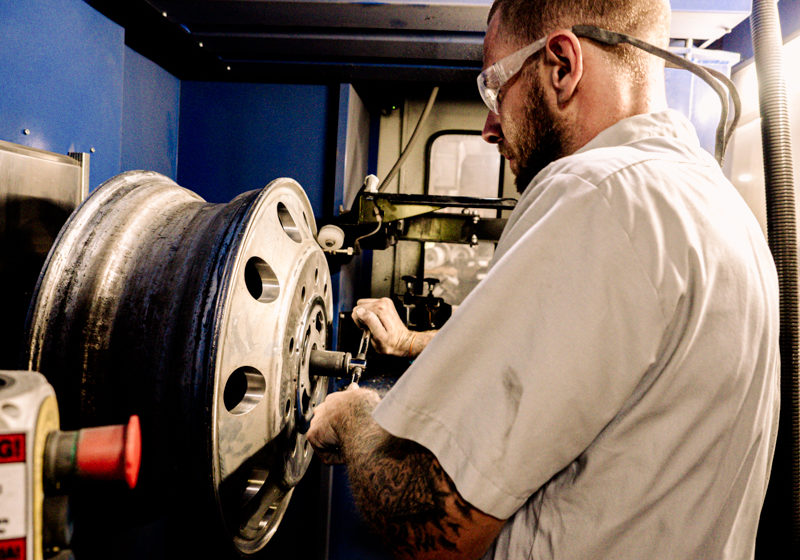

Aluminum Wheels

Best-One Kentuckiana can also refinish your aluminum wheels. We finish aluminum wheels by hand to eliminate the warping that can result from machine buffing. Warped wheels can cause an improper fit to hub or tire, either of which can be catastrophic. Our expert finishers will bring back the original shine of your wheels, without sacrificing your safety.

aluminum wheel polish Process

Thorough Inspection

Each incoming wheel is thoroughly inspected for cracks, rust-through, or other damage that may make the wheel unserviceable. Wheels found unfit for service are removed from the process.

Hand preparation

Each wheel is hand buffed and cleaned to remove large debris and burrs off the wheel.

Mounting

Each wheel is then mounted in the polishing machine and scanned for warping.

Sanding

Then the wheels go through a sanding process to remove all road debris, rust, and corrosion.

Buffing

Then the wheels go though a buffing process to give a showroom finish. The wheel then goes through another scan to ensure the wheel is defect free.

Final Inspection

Every finished wheel is subjected to a final inspection to guarantee a like-new appearance.

Ready When You Need Them

As part of our Fleet Management and Mounted Tire Programs, we can refinish your wheels when your tires are being replaced, repaired, or retreaded. That way, when you call on our service technicians for a new tire, it will be delivered on a wheel – clean, polished, and ready to roll.

80+ years of serving customers

They supply every tire for us from school buses to our light duty equipment. Their prices are competitive and their service and delivery are second to none.

It’s nice to have a single vendor that handles both our on-road and off-road tire needs.

I think the biggest attribute is the personal connection. I can call our sales rep’s cell phone, and if we really need something, it will be here before the end of the day.

Best-One’s service is unbelievable! Having the right tires keeps our fleet safe, and the wheel reconditioning keeps our fleet looking good.

Our community deserves and receives quick response times in an emergency. I consider Best-One a vital partner in serving the Jeffersonville Fire Department.

For over 40+ years we’ve partnered with Best-One. They provide proven solutions that keep me rolling when our equipment has Gotta Go!

All our equipment runs on a schedule that has to be met. Downtime is not an option. That’s why we ride on tires from Best-One Kentuckiana.

Having a team I can lean on with great service helps my crew stay on track. I have confidence in in what I get from Best-One… they keep me moving!

Our sales rep has gone above and beyond taking care of our account and keeping us informed of the best application of brands & tires.

They have a good inventory of tires on their lot, and most generally provide same day service, which means less downtime waiting on a tire.